Basri

An interactive and immersive experience that promotes human creativity through creation of Islamic-inspired design.

PROJECT TEAM

Maxim Safioulline

Michael Coty

Maxim Safioulline

Michael Coty

My role was to design and build

Basri’s experience, while Maxim

developed code, planned hardware,

and guided the project.

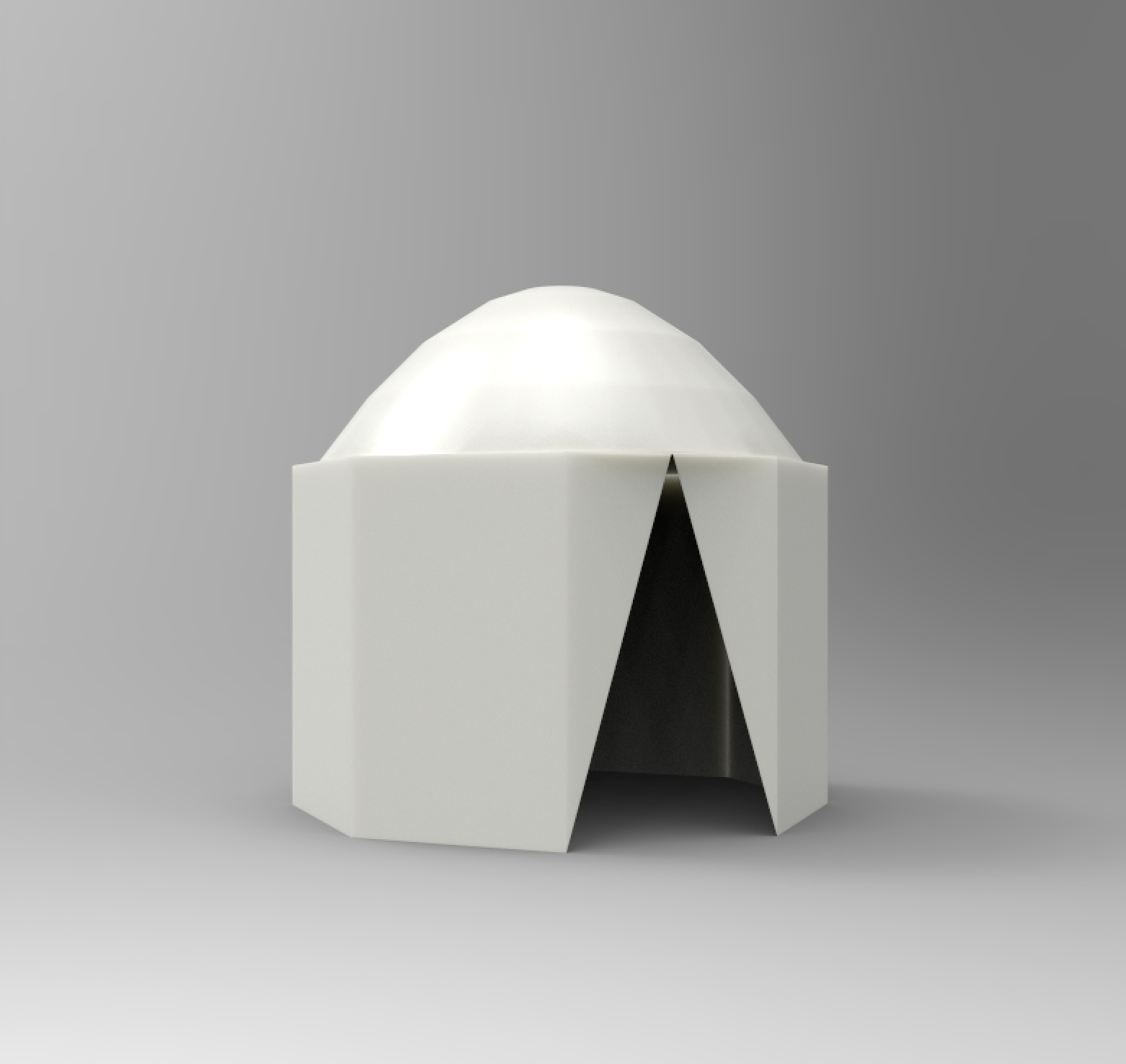

We created a small pavilion where

participants interact with an immersive

360-degree projection of Islamic

design patterns.

Basri’s experience, while Maxim

developed code, planned hardware,

and guided the project.

We created a small pavilion where

participants interact with an immersive

360-degree projection of Islamic

design patterns.

Research

History is the foundation of Basri.

Researching the Islamic Golden age

helped shape constraints.

Researching the Islamic Golden age

helped shape constraints.

Sketching

Sketching object forms, exploring tactile

interactions and possible scenarios helped

direct digital / physical decisions.

interactions and possible scenarios helped

direct digital / physical decisions.

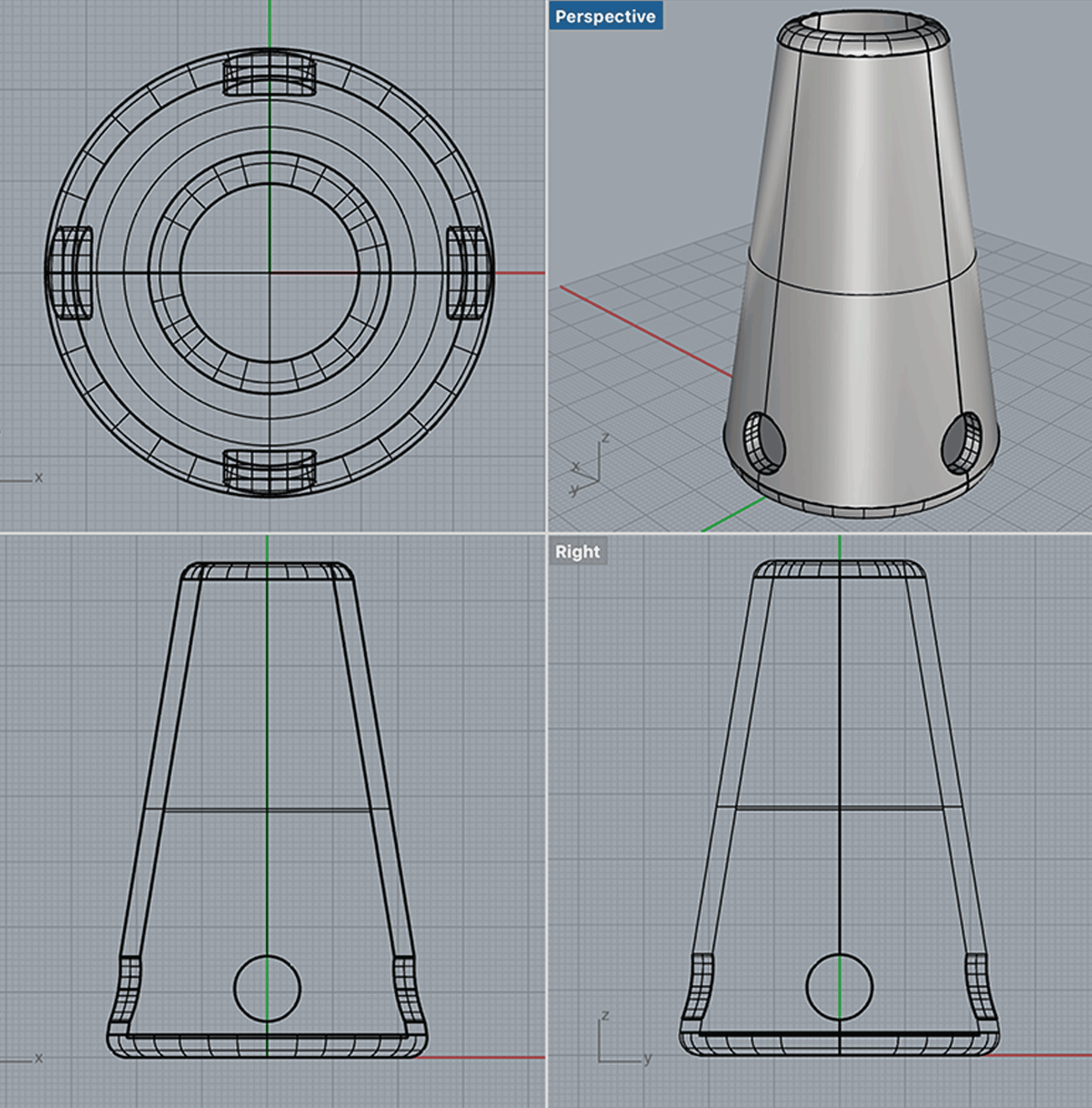

Digital Design

Schematics, 3D models, and rendering

were created to help inform size and space.

Understanding the objects form,

material, and finish influenced

a final design.

were created to help inform size and space.

Understanding the objects form,

material, and finish influenced

a final design.

Prototyping

After creating schematics and 3D

renders, physical protoyping took

place in the shape of a PVC frame.

renders, physical protoyping took

place in the shape of a PVC frame.

Installation

Basri was installed and interacted with

during the first ever SMC IxD senior show!

This project is still in progress!

during the first ever SMC IxD senior show!

This project is still in progress!

Emotional Ecosystem

The human brain is an emotional ecosystem that raises many curiosities. Is emotional data valuable, can it be captured, and represented?

PROJECT TEAM

Casey McCallister

Sasha Bassiouk

Michael Coty

Casey McCallister

Sasha Bassiouk

Michael Coty

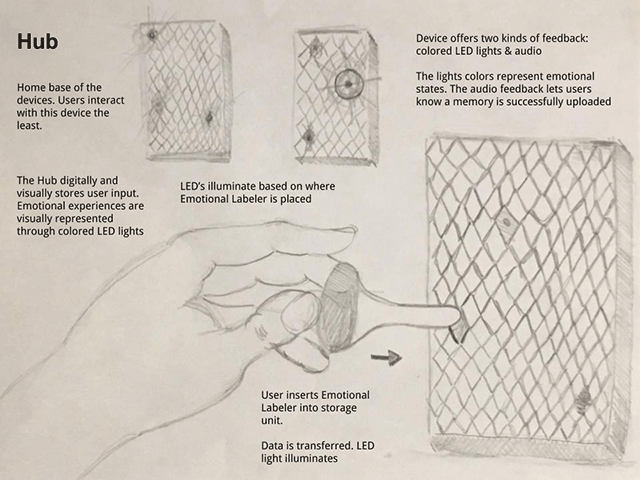

My role for this project was to design

the emotional ecosystem’s Hub.

This peice is the home base, and data

storage center of the system.

There are 3 pieces in the system.

Casey worked on the labeler, and

Sasha worked on the headband.

the emotional ecosystem’s Hub.

This peice is the home base, and data

storage center of the system.

There are 3 pieces in the system.

Casey worked on the labeler, and

Sasha worked on the headband.

Research

Exploration and research is the foundation

of this project.

of this project.

Sketching

During this process I explored how tactile

interactions might take form.

Sketching object forms and possible scenarios

directed digital and physical decisions.

interactions might take form.

Sketching object forms and possible scenarios

directed digital and physical decisions.

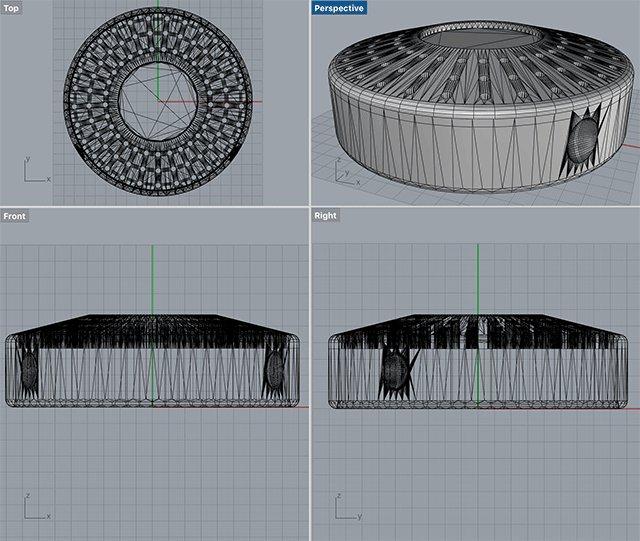

Digital Design

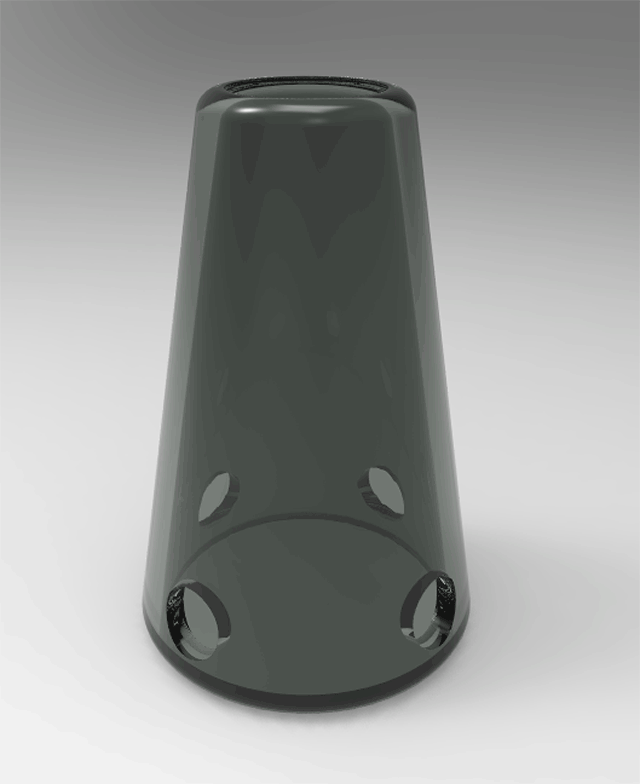

Schematics, 3D models, and rendering

were created.

Understanding the objects form,

material, and finish helped create

a cohesive system.

were created.

Understanding the objects form,

material, and finish helped create

a cohesive system.

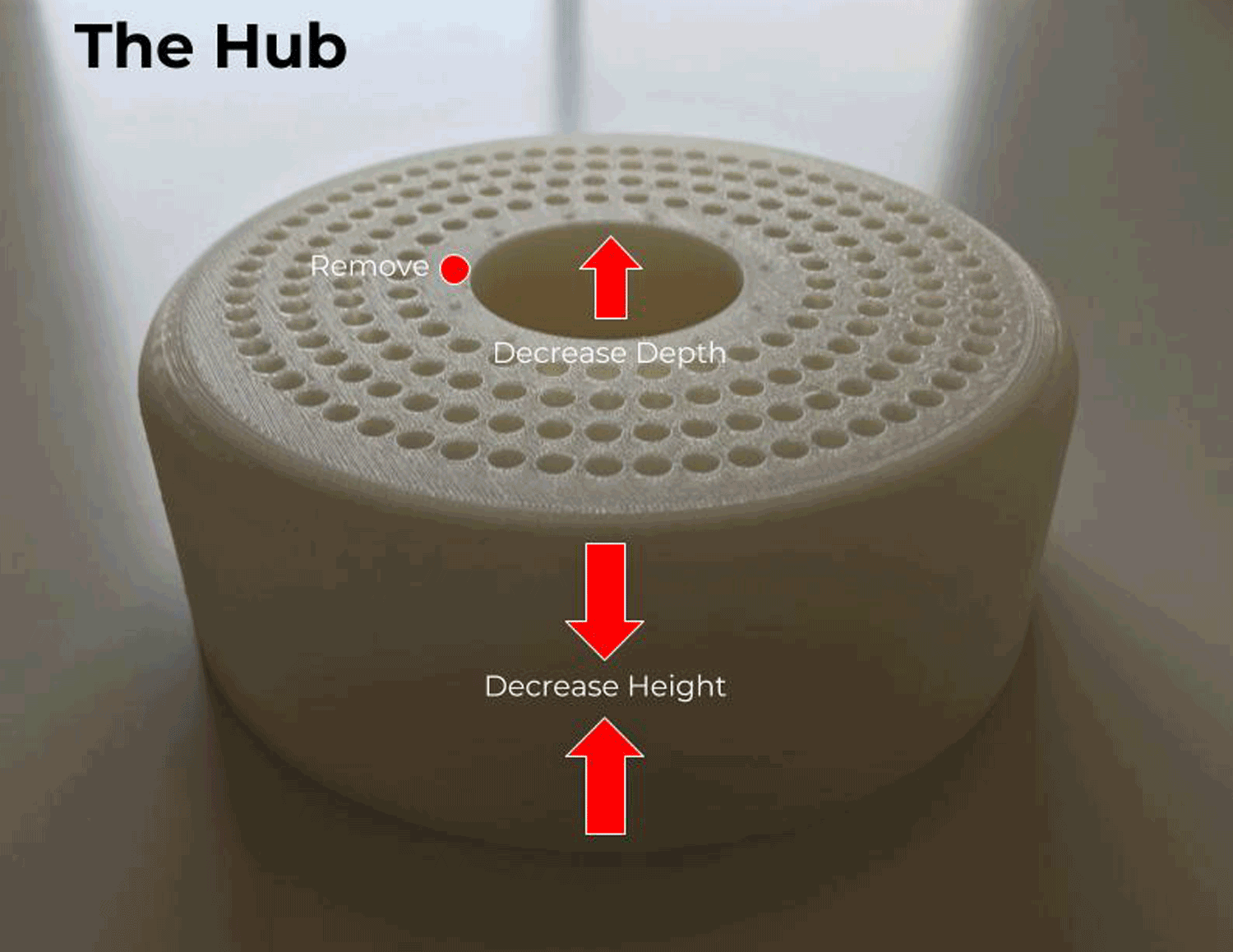

Prototyping

After paper prototyping and the first 3D

print, feedback helped iterate and refine

the design.

Physical prototyping led to an understanding

of the objects ergonomics and feel.

print, feedback helped iterate and refine

the design.

Physical prototyping led to an understanding

of the objects ergonomics and feel.

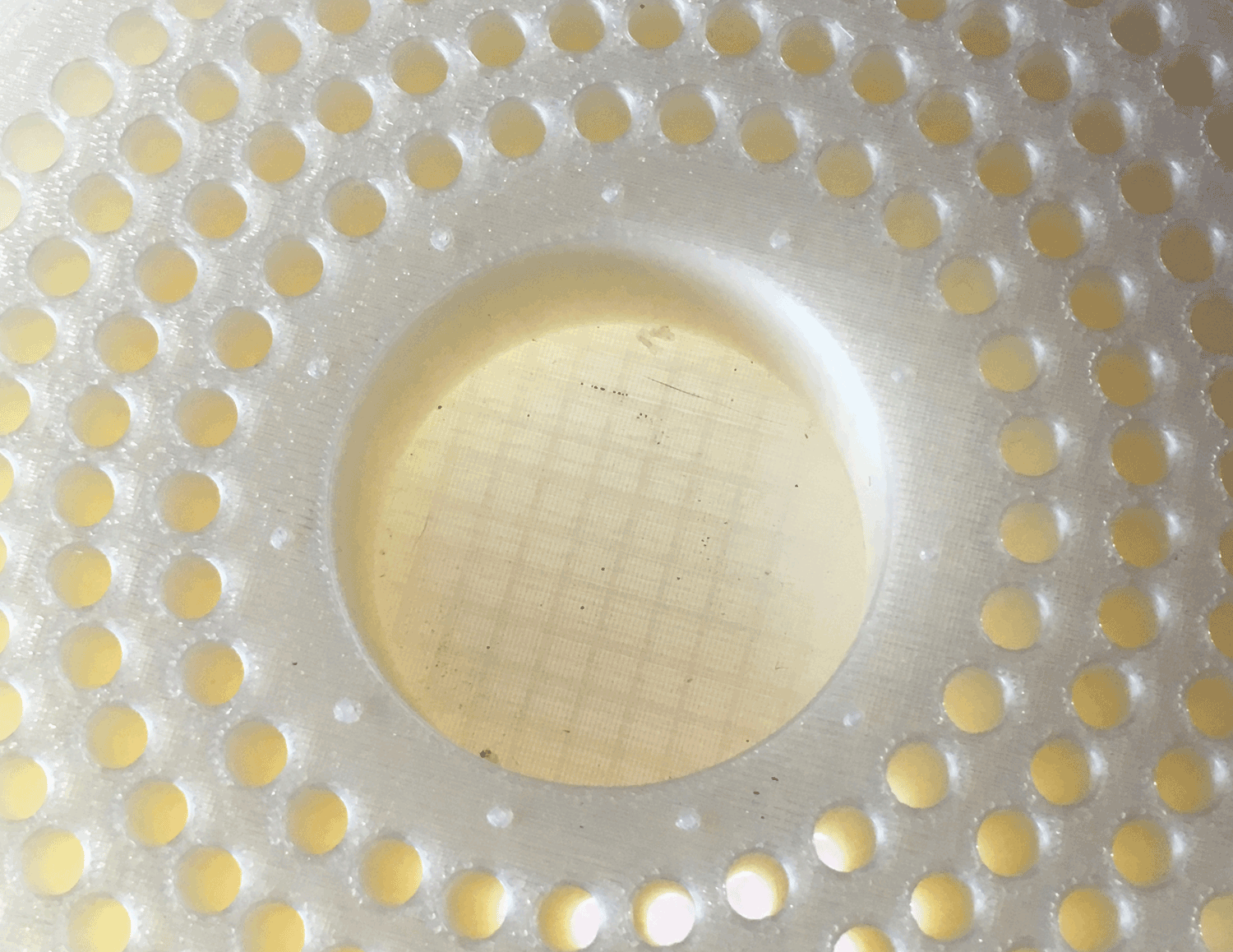

3D Printing

There were two rounds of 3D printing.

The first prototypes were to inform

shape, and ensure the system fit.

The second print was our final for

this project.

The first prototypes were to inform

shape, and ensure the system fit.

The second print was our final for

this project.

H2GO

A wearable for surfers that measures water quality by checking for harmful contaminants

PROJECT TEAM

Michael Coty

Michael Coty

H2GO wearable provides surfers

a piece of mind while in the water.

Surfers are exposed to harmful

contaminants while in the ocean,

often without even knowing until

its too late.

H2GO monitors water levels actively

and passively, providing a record of

previous / current water conditions.

a piece of mind while in the water.

Surfers are exposed to harmful

contaminants while in the ocean,

often without even knowing until

its too late.

H2GO monitors water levels actively

and passively, providing a record of

previous / current water conditions.

Digital Design

Schematics, 3D models, and

rendering helped inform size,

form, plus material finish.

rendering helped inform size,

form, plus material finish.

UI Design

The interface visually represents data

to create an understand of conditions.

H2GO logs water quality and publicly

shares the information.

to create an understand of conditions.

H2GO logs water quality and publicly

shares the information.

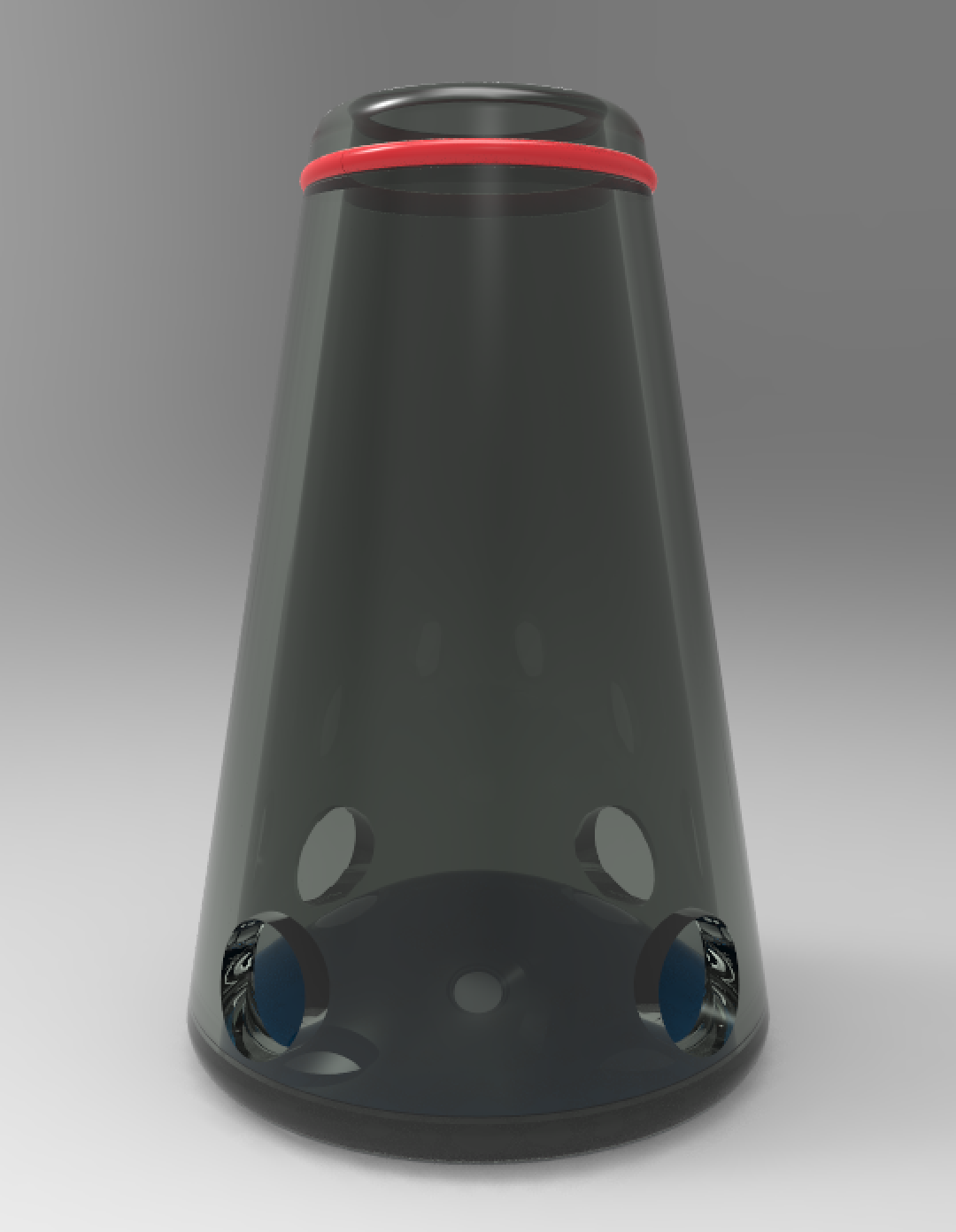

Final 3D Render

Green means go, and red means no!

H2GO is simple and easy to use. When

exposed to water that is considered

harmless it glows green, while glowing

red when contaniments are detected.

The hardware is simple and is an ocean

intended wearable.

H2GO is simple and easy to use. When

exposed to water that is considered

harmless it glows green, while glowing

red when contaniments are detected.

The hardware is simple and is an ocean

intended wearable.

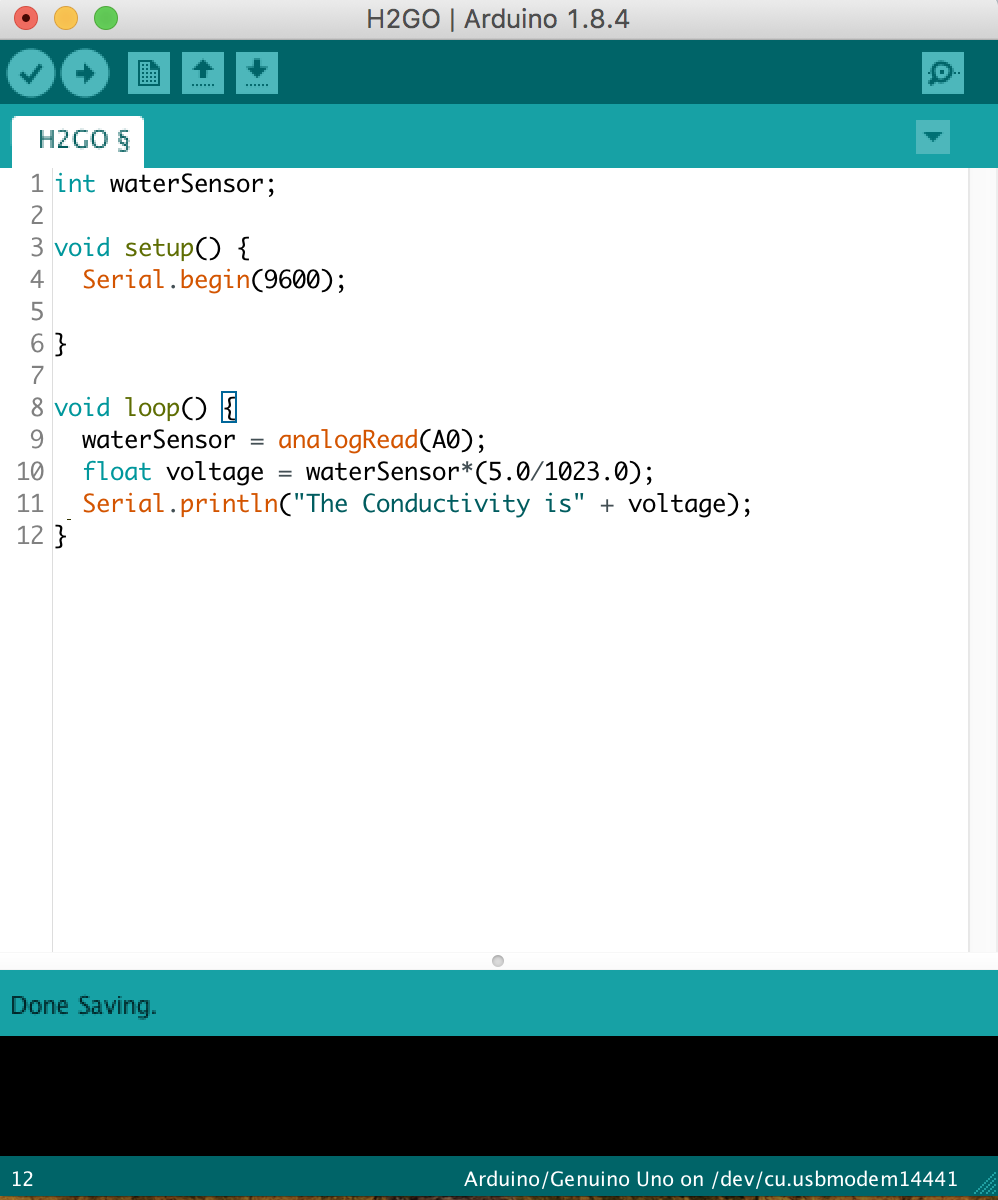

Prototyping

H2GO is still a prototype. At this point

arduino and a basic water sensor read

voltage to detect contaniments.

Protoyping will continue to evolve

with more testing, and feedback.

arduino and a basic water sensor read

voltage to detect contaniments.

Protoyping will continue to evolve

with more testing, and feedback.

Operation CMD

How migh we help students new to campus feel welcomed and informed?

PROJECT TEAM

Edwin Rodriguez

Michael Coty

Evan Pierre

Edwin Rodriguez

Michael Coty

Evan Pierre

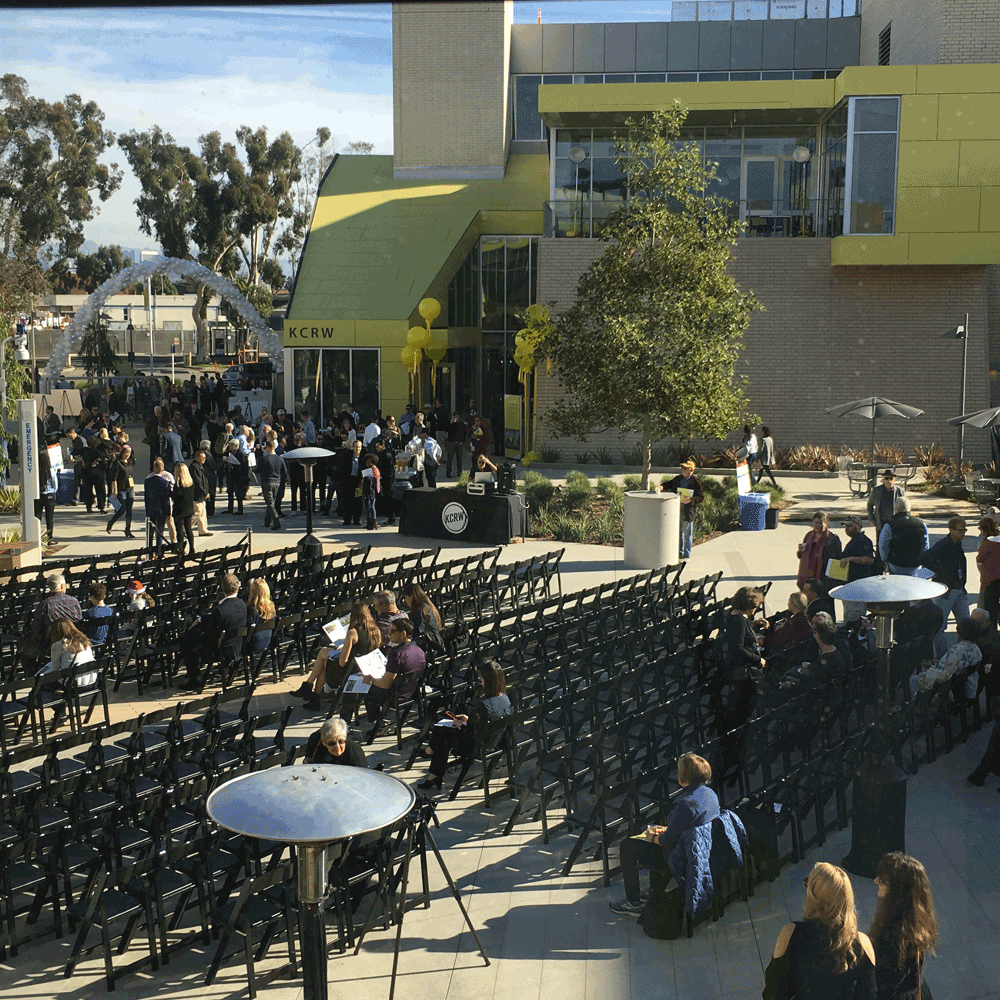

Santa Monica College’s new CMD

campus needed a little help!

We decided to help students feel

welcomed and informed during their

first days at school.

campus needed a little help!

We decided to help students feel

welcomed and informed during their

first days at school.

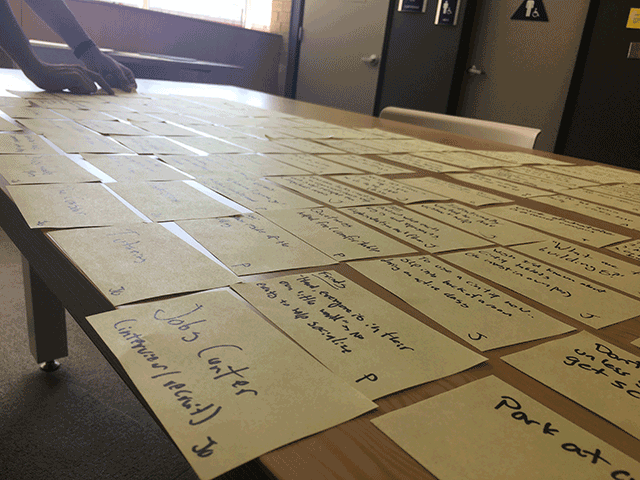

RESEARCH

We researched, interviewed students,

and synthesized findings into insights.

The final affinity map led our team to

prototype 3 ideas.

We persued the CMD Scavenger Hunt.

and synthesized findings into insights.

The final affinity map led our team to

prototype 3 ideas.

We persued the CMD Scavenger Hunt.

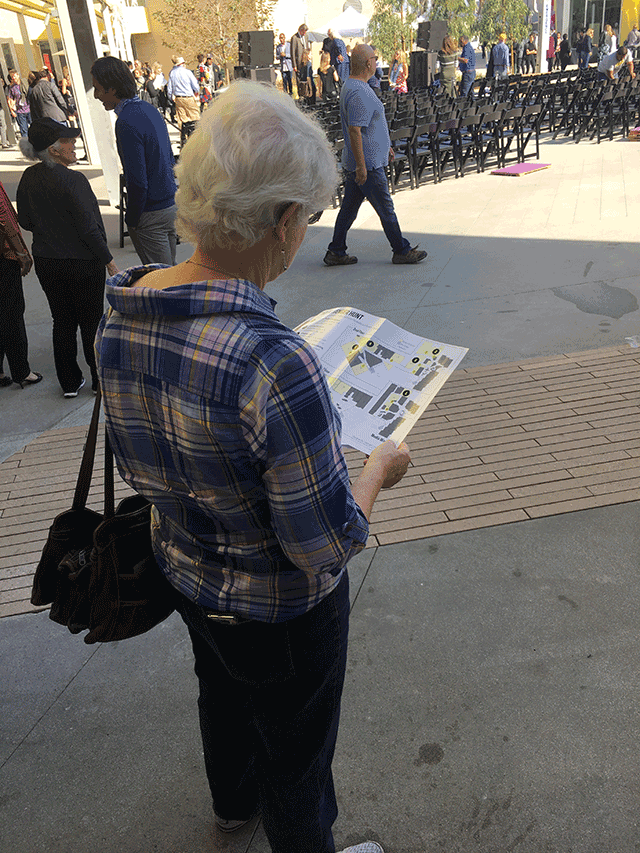

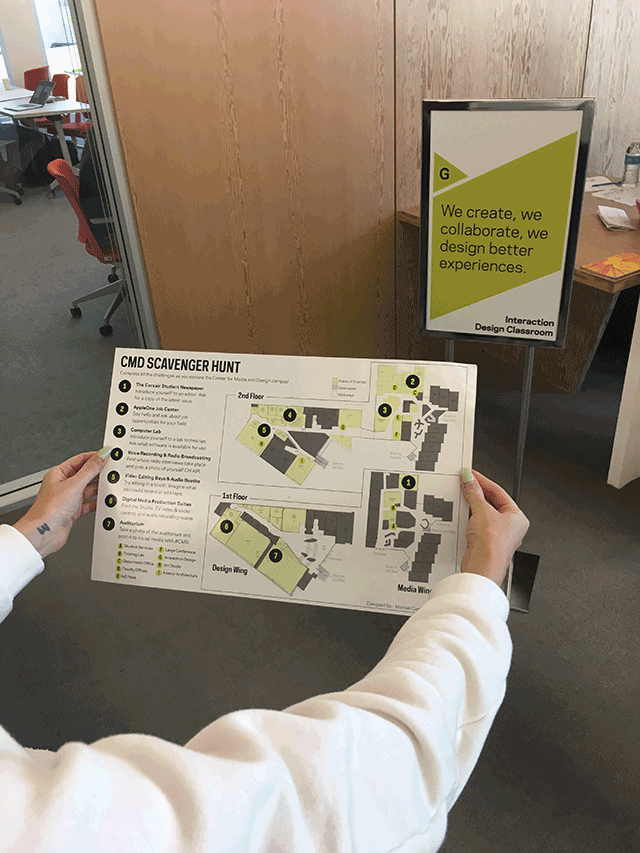

Prototyping &

User Testing

User Testing

We paper prototyped the scavenger hunt

and the complimentary sinage.

Students were given a series of tasks,

and earned a mystery prize upon completion.

Students had fun, and became more

educated about their campus. All feedback

collected shaped the final design.

and the complimentary sinage.

Students were given a series of tasks,

and earned a mystery prize upon completion.

Students had fun, and became more

educated about their campus. All feedback

collected shaped the final design.

Opening Event

Our design was a part of CMD campus

opening event!

The scavanger hunt maps led people

throught the campus while the signage

confirmed the right direction.

opening event!

The scavanger hunt maps led people

throught the campus while the signage

confirmed the right direction.

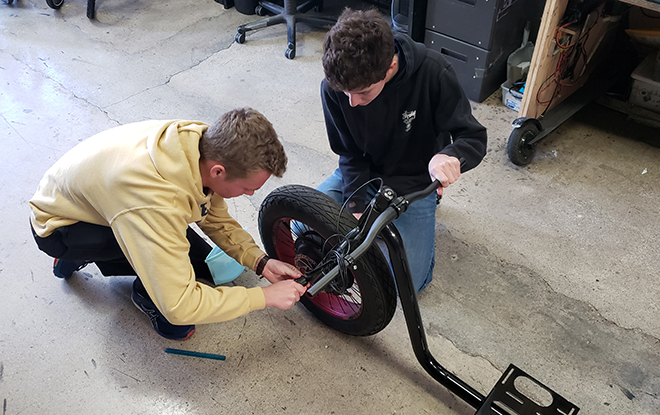

The Drift Trike Project

Welcome to the Electric Drift Trike Project!

In 15 steps we will assemble a working electric drift trike.

![]()

In 15 steps we will assemble a working electric drift trike.

Step 1: Pegs

Thread each peg onto the front wheel axel. Use an allen wrench to tighten pegs down.

Step 2: Throttle

Install the throttle onto the handlebars by tightening the set screw with a 3mm allen key.

Step 3: LCD Screen

Use a phillips screw driver to secure the power level selector. Strap the LCD screen by its rubber clamps.

Step 4: Grips

Using a 3mm allen key install both grips.

Step 5: Setting the Components

With a phillips screw driver, 3mm, and 4mm allen keys tighten down handlebar components.

Step 6: Wire Routing

With a brake cable (provided as a tool) and electrical tape, gentley route wires through the frame.

Step 7: Wiring Clean Up

Clean up the appearance of the wires with wire loom clips.

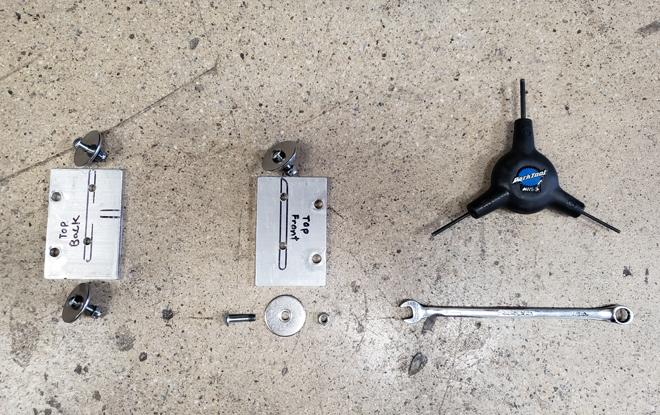

Step 8: Motor Controller Mounts

Mount the motor controller adapter plates with their hardware, 8mm crescent wrench, and 3mm allen key.

Step 9: Motor Controller

Mount the motor controller, with hardware, 8mm crescent wrench, and 3mm allen key.

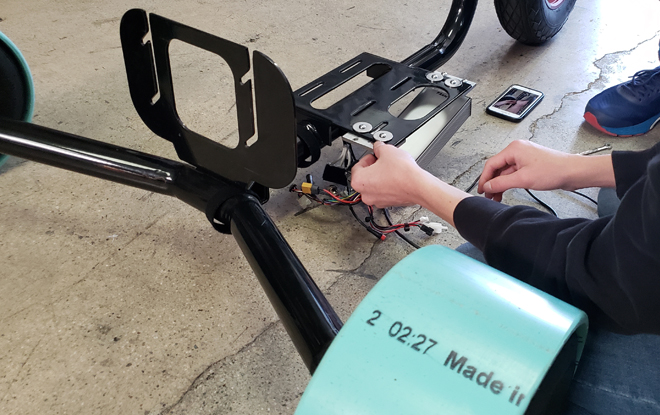

Step 10: Motor Controller Wiring

Connect the throttle, lcd screen, brake inhibitor, and battery to the motor controller.

Step 11: Motor Connection

Connect the motor wires to the motor controller.

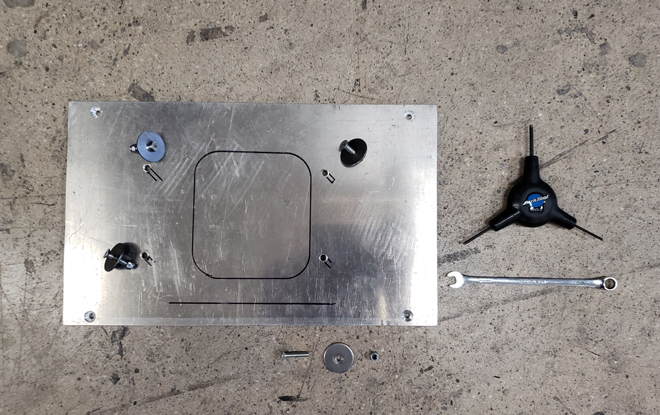

Step 12: Battery Mount

Bolt the battery adapter plate to the frame. Use the hardware, 8mm crescent wrench, and 3mm allen key.

Step 13: Battery

Fasten the battery to the battery adapter plate. Use hardware, 8mm crescent wrench, and 3mm allen key.

Step 14: Seat

Mount the seat to the frame. Use seat hardware and 4mm allen key.

Step 15: Final Tune

Adjust components to comfort and give a final torque to each hardware.

Before Every Ride

- Ride in a safe location

- Always wear a helmet

- Ride with friends present

- Start in a low power level

- Inflate tires to max pressure (printed on tire sidewall)

- Perform brake check to be sure the wheel stops

- Make sure throttle and brake inhibitor function

Have fun and be safe!